Paint Density:

Measuring film thickness

A number of factors affect coating thickness, including improper thinning, environmental conditions or mixing ratios when using two- or multiple-component coatings. These are all minor things that can add up to a major problem.

by Susan Brimo-Cox

but it’s not. Coatings manufacturers put a lot of work into formulating their products, with each product designed to work in specific environments and provide specific protective qualities. For example: Exterior house paint protects a dwelling from the weather. A coating on a submarine is designed to protect the ship’s hull from the ocean’s watery environment. And in the case of tanks, the coating may protect the vessel’s contents from the tank itself or protect the tank from its contents. Often, the thickness of the coating is critical in ensuring there is not a premature failure.

“Specifications for film thickness are based on testing criteria the manufacturers have tested to,” explains Rob Roy, a National Association of Corrosion Engineers inspector and instructor in Houston, Texas. Therefore, coatings are “known to do certain things at certain thicknesses.”  Recommendations for appropriate coating thickness may vary in residential, commercial and industrial environments, says Jeff Donius, president and owner of Premier Veneers Custom Painting and Decorative Concrete in Romeo, Mich. But in every instance the “coating needs to be thick enough to withstand the environment,” be it foot traffic, machinery, abrasion or chemicals. If the coating thickness isn’t specified in the job contract, “the [technical] data sheets are important and will tell you the advisable range of thickness per coating,” he adds. Recommendations for appropriate coating thickness may vary in residential, commercial and industrial environments, says Jeff Donius, president and owner of Premier Veneers Custom Painting and Decorative Concrete in Romeo, Mich. But in every instance the “coating needs to be thick enough to withstand the environment,” be it foot traffic, machinery, abrasion or chemicals. If the coating thickness isn’t specified in the job contract, “the [technical] data sheets are important and will tell you the advisable range of thickness per coating,” he adds.

A number of factors affect coating thickness, reports Roy, including improper thinning and applying the coating in the wrong environmental conditions or the wrong mixing ratios when using two- or multiple-component coatings. “These are all minor things that can add up to a major problem.”

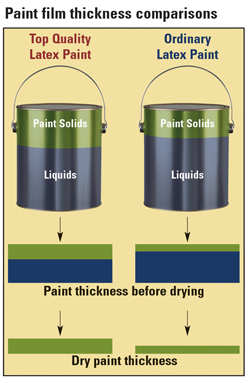

Joe Walker, vice president of Elcometer Inc. in Rochester Hills, Mich., says the application technique, such as applying by hand or by sprayer, can also affect coating thickness. Other factors to consider include porosity and the surface profile of the substrate, Walker adds. “If you have a porous material, you have to consider absorption.” With regard to surface profiles, he explains, “think of it as snow [in] the mountains. If you have a 4-mil surface profile and apply 2 mils of coating, you’ll have an uneven surface coating, [much like] snow in the valleys,” but not on the mountaintops. The composition of a coating and its film build, as well as a product’s solids content, also control film thickness, according to John Stauffer, technical director of The Rohm and Haas Paint Quality Institute in Spring House, Pa. In the case of paints, the film thickness you have after the paint dries is determined by the proportion of solids to liquid that are in the paint. “Generally speaking, higher quality paints have higher volume solids than do economy paints, and so they dry to a thicker film for a given spread rate.”

The rule of thumb, in ideal circumstances, is that “the vehicle to solids ratio will tell you how much dry thickness you’ll have; though sometimes it defies the laws of physics,” observes Paul Gardner Jr, president of Paul N. Gardner Co. in Pompano Beach, Florida.

Say you have a coating that contains 50 percent solids. You apply it on a perfectly smooth substrate at a thickness of 10 mils when wet. When it is dry, 50 percent will be gone, and you’ll be left with a 5-mil cured coating. If you apply a 10-mil coating that has 75 percent solids, you’ll have a 7.5-mil cured thickness.

What is a mil? One-thousandth of an inch; 1,000 mils equal 1-inch. It’s a linear measurement.

So, how much of a coating product do you need for a particular project? Roy says the manufacturer’s data sheets give you a solids-by-volume number and a projected wet-film thickness — as well as dry-film thickness — that will help you with your calculations. Say you are using a product that has 100 percent solids and will cover 1,604 square feet at 1-mil thickness. If you need a dry coating of 4 mils, you need to divide 1,604 by 4 to learn the product will cover only 401 square feet at that thickness.

use more material on textured surfaces. For example, “you have to take the blast profile into consideration. An average blast profile on new steel is 1.5 to 2.5 mils,” Roy explains. To achieve the correct coating thickness, “you have to fill the valleys, then measure from the peaks.”

Are you using a thinner? That, also, would affect the equation. You would derive the correct wet-film thickness you need by dividing the desired dry-film thickness by the percent of solids by volume plus the percentage of thinner you add.

And don’t forget to take into account mixing and application losses. Walker recommends adding 30 percent to the calculated amount of coating material needed to covers those losses.

“Putting the right amount on is important to [the] economics” of a job, says Gardner. “You need to apply a certain amount for the protection you need. More than that is unnecessary and could be expensive.”

Walker agrees. “Most people think more is better, but, if you apply [more than you need,] you’re throwing money away.”

Wet-film thickness can be measured by a variety of gauges, but notch — also known as step or comb gauges — are inexpensive and the most commonly used field gauges. A notch gauge has calibrated notches on its edges. You place the gauge squarely into the film and on the substrate when the coating is wet. When you remove the gauge, look at the notches. The film’s thickness lies halfway between the last coated notch and the adjacent uncoated notch. While not precise, notch gauges are good for approximating film thickness and they come in aluminum, steel or plastic.

If the measurement of the wet coating is more critical, other devices, such as an eccentric roller gauge, lens gauge or needle micrometer can be used.

Dry-film thickness can be measured either in a destructive or non-destructive manner. “Non-destructive paint thickness gauges generally fall into one of three categories,” reports David Beamish, general manager of DeFelsko Corp. in Ogdensburg, N.Y. Use “magnetic gauges for measuring over steel, eddy current gauges for measuring over most other metals and ultrasonic [gauges] for measuring over non-metal substrates.”

Magnetic gauges measure the attractive force between the magnet in the gauge and the steel substrate. As the coating thickness increases, the magnet becomes easier to pull away. By measuring the pull-off force, you can determine the film thickness. “The weaker the force, the thicker the coating,” observes Beamish. Magnetic gauges are rugged, simple to use and inexpensive. Typical tolerances can range from plus-or-minus five percent to 10 percent.

Electronic and eddy current gauges are more expensive, but also more accurate, with a typical tolerance of plus-or-minus one percent. Plus, “they are faster and provide a variety of options such as the ability to download stored measurement results to a printer or computer,” Beamish explains. They also allow you to probe different part shapes and sizes or rough and uneven substrates.

Ultrasonic gauges are ideal for measuring coatings over non-metal substrates, such as wood, concrete and plastic. These instruments send a pulse through the coating. The pulse is reflected back from the substrate and converted into an electrical signal that is used to determine the film thickness. “In some circumstances, individual layers in a multi-layer system can be measured,” Beamish says. The typical tolerance for ultrasonic gauges is plus-or-minus three percent.

Destructive tests to measure film thickness generally require cutting through the coating to the substrate. The coating is then measured with a micrometer or by viewing it microscopically. Another method is to weigh a section of the substrate before and after coating. Laboratories are best suited to handle these tests.

Experienced coating applicators know that two coats are better than one thick coat for a uniform film. But, if you’re applying multiple coats, how do you know when you have enough? Say you’re spraying and back-rolling for an even application. How can you be sure that the roller isn’t picking the material back up and giving you a thinner coating? Measurement, that’s how.

“We’re all creatures of habit. Sometimes what worked in one environment won’t work in another,” cautions Roy. “When you’re starting a job, make sure the system and product will function in the environment it’s intended.”

As a contractor, you’re more likely to take wet-film measurements. Inspectors are more likely to take dry-film measurements. Whether you measure wet or dry, make sure you have the correct gauge. “The least expensive gauge may work, but look for a gauge that is calibrated to the needed standard,” says Gardner. “If you can’t prove you put on the specified coating, you don’t have traceability.”

And, perhaps, this is the bottom-line benefit of measuring film thickness. As Donius points out, “If you do take the trouble to measure the coating and document the temperature, moisture [and other conditions], you have a stronger case with the manufacturer if there is a product failure; and it provides the project manager or owner an added sense of confidence in the workmanship.”

|