Peter Pandelopoulos, DP Painting Company, Sacramento, California

Warriors of the Painting Trade

by Bob Graham

, using a crew of 40 painters who skillfully shifted from prep work to spraying to touch-up in a manner designed to encourage absolute efficiency without sacrificing quality.

It’s a delicate balance, but one that DP Painting Inc., a Sacramento, Calif.-based production painting company, and scores of other painting operations manage every day. In the world of painting, production painting is the highwire act. “You have to do it fast and keep to a schedule, but you have to have quality too,” says Peter Pandelopoulos, president of DP Painting. The company opened in 1992 and was incorporated in 1996.

DP Painting has 55 painters, who work at 30 different job sites. About 16 people work at eight new subdivisions in Sacramento, while the bulk of DP Painting’s employees, about 40, work at 22 sites in Reno, Nevada, one of the fastest growing areas in the country.

Pandelopoulos’ painters are supposed to complete two jobs each a day — average. His best painters can complete four a day.

Of course, getting it done isn’t enough. Production painting requires quality, too.

Pandelopoulos estimates that his crews match about 90 percent to 95 percent of the quality of custom painters. “It isn’t perfect, but there’s a certain level of quality that builders are looking for,” Pandelopoulos says. “You have to do it well and keep on schedule to keep the builders and the home buyers happy.”

Production painters come and go frequently because they meet the speed, but not the quality requirements, especially at a time when Pandelopoulos says builders in California and Nevada are looking for a higher level of quality, for which they are willing to pay more.

Production painting is a competitive arena. In DP Painting’s case, between 6 and 12 companies are bidding for the same job, often with prices that nearly match. As a result, it’s the company with the best reputation for meeting scheduling requirements and as well as quality needs that gets the work.

“What kills you is if you have to go back. You really need to do it right the first time,” explains Pandelopoulos, 40. He came to the U.S. from Australia in 1987, and married his wife, Gina. He needed a job and his father-in-law, Jim Mamalis, was a painter. Pandelopoulos started painting and slowly worked his way up to ownership by 1992.

Over the last nine years, he’s perfected the production painting regimen to encourage maximum efficiency and the best quality possible.

His crews range in six from two to five painters, depending on workload. Over three days, crews work in the following system: first day, prep house and complete masking; second day, spray flats and enamels; third day, paint casings and doors. The approach is the same, whether the house is 1,400 square feet or 3,000 square feet.

DP Painting’s workers, many of whom have been with him for more than eight years, are trained using the same system. As apprentices, they perform prep work. If they succeed at prep work, they can move to spraying and then, if really skilled, get to do touch-up work. By that time, they’re qualified journeymen.

Because of the unusual deadline requirements that can occur as buyers anxiously await the completion of their homes, many of DP Painting’s workers are cross-trained. “Most of the guys know all the jobs so they can fill-in where necessary,” says Pandelopoulos.

Pandelopoulos’ painters, who come with various painting backgrounds, vary in their abilities. Some flourish in his system, while others languish. Pandelopoulos tries to encourage his employees to meet the speed and quality standards. “Some guys just pick it up real quick, but others take a while. But if they want to make more money, they need to figure it out,” he says.

He pays his top performers well, figuring that it’s better to retain his good employees than to reinvest in training someone new.

Of all his employees he asks that they perform their functions right the first time so they don’t have to return to jobs.

DP Painting is always trying to improve its operations so it can be more efficient. For the last few years, the company has focused on getting painters the right tools each day. In 1997 Pandelopoulos figured he had spent more than $18,000 in small equipment like putty knives, brushes, etc. “I couldn’t believe it, but it was right. So much stuff was being lost or misplaced because the guys knew they could get a new one the next day,” he says.

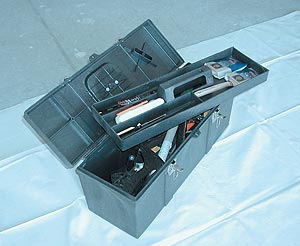

Pandelopoulos decided to charge his men for their tools. New employees pay $225 for a grip, which includes two brushes, a putty knife, a wavy brush, a weenie roller, a 7-inch roller, a 4-inch roller, a Stanley knife, a hammer, a brush extender, a screwdriver, a caulking gun and a 4-foot extension pole. He usually takes the grip fee from the employee’s first four paychecks, and he charges his painters who lose tools. The kit, which comes in a tool box, standardizes the equipment his crews have and use. That way they are better able to meet the same quality requirements each day.

“It’s great. The guys have no excuse for why they can’t do a job. They have all their tools,” Pandelopoulos says. “They also treat it all a lot better because it’s their own.”

When deadlines approach, DP Painting’s crews often have to pull extra hours. But Pandelopoulos tries to keep his painters fresh at all times. Most crews work up to 8 hours a day, completing two to four houses in a three-day cycle. But when deadlines are approaching those hours can stretch to 10 or 12 a day. If they work one or two long days, Pandelopoulos cuts the next day short. “I can’t afford to work them hard for two or three days, then lose them for the next two so we try to keep it managed,” he says.

To do that, his foremen try to schedule efficiently. Builders fax their schedules over on Thursday. On Friday, DP Painting’s foremen put the schedule on their big board, trying to match painters to jobs that need to be completed. By Monday, the work has begun. And by Thursday, the process starts anew.

“It’s a continuous flow,” Pandelopoulos explains. “You have to keep up or else you can get behind by a week in a month. A day here and a day there doesn’t mean a lot to most painters, but to us a day a week can mean a week by the end of the month. Plus it can screw up the deadlines of all the other people working the site.”

Each painter carries his own grip and is responsible for the tools it contains. Each painter carries his own grip and is responsible for the tools it contains. |

In the last six months, DP Painting has had to turn down about a dozen jobs because Pandelopoulos couldn’t find another 30 painters to work for him. “Labor shortages are a reality,” he notes.

His frustration with staffing limitations is minimal. He fears growing too big, too soon. Because of growth over the last few years, he’s had to put more power in the hands of his foremen, and he’s looking for more people who can manage the work. Pandelopoulos does all the bidding, but only visits a handful of job sites each week.

Pandelopoulos is finding that the decision of what paint to use is increasingly being made by builders, who are signing deals with paint manufacturers. For his work in Sacramento with Wingcraft Homes, he’s required to use Sherwin-Williams paints.

Between Sacramento and Reno, DP Painting has enough work to keep his crews working for at least a year. For the last four years, his crews have been busy in all months, which is both a tribute to the number of new houses being built and DP Painting’s ability to schedule well.

“The economy is good, and the builders continue to build houses for all the people who want to move up. And we do what they need to keep that chain going,” says Pandelopoulos.

|