Masking Tape

Preservation and application of the proper product are crucial factors in masking tape's performance.

by Jeff Woodard

skill and precision — plus quality materials — especially around the edges. A painter’s choice of masking tape can make a significant impact on the appearance of the finished product. The proper selection results in customer satisfaction. A tape ill suited for the job causes headaches — and slows production speed.

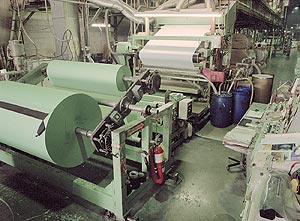

Masking tapes are basically composed of two types of paper, says Harry Young, owner of Tape Specialties in Concord, Ontario, Canada. “The most common is crepe masking paper. It has a rough surface to it,” says Young. “There is some elongation in the paper, it has stretch in it; on corners, it won’t break or tear as easy. It also doesn’t fit as tight to the wall surface, so you need to use your nail to prevent edge bleed from it.” The other paper, adds Young, is a flat-backed material used on low-tack masking tapes. “It’s basically very smooth and quite thin. It yields a much finer edge.”

Tape Specialties, according to Young, is the only manufacturer to successfully develop a water-based, rubber-based adhesive system for masking tapes. Tape Specialties, according to Young, is the only manufacturer to successfully develop a water-based, rubber-based adhesive system for masking tapes.

Water is not uncommon in acrylic adhesives, but nobody has been successful in developing a water base using rubber,” explains Young. “Since 1982, we have manufactured a high-quality masking tape that is totally environmentally friendly. No pollutants whatsoever are used in the manufacturing process.”

Young says the high ultraviolet resistance of Tape Specialties’ Painters Mate Green® tape enables painters to leave the tape on a window exposed to sunlight for eight or nine days, and then remove the tape easily. In applications where ultraviolet rays are not a factor, the tape can be left on the surface for up to two weeks and still be removed cleanly, says Young. “It’s basically designed to do almost anything a painter wants a masking tape to do, do it well, and do it at a reasonable price.”

An effective masking tape should adhere to a surface, protect the surface from paint, and remove without residue and without peeling paint. “The biggest difference in masking tapes today is there are so many products on the market that are not designed for painting but are still called ‘masking tape,’” said Young. “‘Masking’ is considered any paper tape in a hardware or paint store. Many are not designed to have good removability.” Unique to Tape Specialties are rubber based tapes specially designed to be removed easily weeks after their application.

The longer a rubber-based tape remains on a surface, the tougher it is to remove. “Acrylics don’t build adhesion the same way,” says Young. “They can be left on longer and still come off easy. The biggest difference between the two is that you are more likely to get paint under the tape with the acrylic because it doesn’t hold to the surface as well.”

A tape’s effectiveness depends on how it was manufactured, the type of glue used and film thickness, according to Gary Lord, owner of Gary Lord Wall Options and Prismatic Painting Studio in Cincinnati. “Some tapes have extremely high adhesion,” says Lord, a contractor and decorative painter by trade, “but for what I do, I don’t need (strong) adhesion, but something that releases easily without residue.”

Masking over wallcovering poses special challenges. Joanne Cooney, Associate Product Manager of LOPAREX, Inc. in Willowbrook, Ill., recommends her company’s low-tack KleenEdge for delicate surfaces such as paper-based and foil wallcovering, though she suggests testing the tape in an inconspicuous area beforehand. Of the less-adhesive tapes, “When you put your finger on the sticky side of the tape, there’s not a tremendous amount of stick to it,” says contractor Ron Franklin, owner of Ron Franklin Painting & Decorating in Sacramento, Calif.

Just as tapes vary in adhesive properties, they are available in multiple colors. 3M broke the tape “color barrier” in the late ‘80s by introducing its blue tape, a crepe-paper base of blue paper with a solvent-based acrylic adhesive. High durability to ultraviolet rays, effective long-term use and easy removability are three of its key features, according to 3M Business Manager Bill Johnson.

In addition to its Painters Mate Green®, Tape Specialties manufactures a Painters Mate Delicate, an acrylic adhesive on smooth, flat-back paper designed for delicate surfaces, faux/decorative finishes and shadow striping. “Because it’s acrylic, it can be left on longer and removed very easily,” says Young. “It’s also tremendously ultraviolet resistant, up to 30 days or more.”

White tape (delicate surfaces) and gold (anchor tape) are among other colored tapes on the market. So, are all colored tapes similar? Are all manufacturers’ blue tapes alike? Are all green tapes the same? No, says Johnson. “We were the ones who invented blue tape,” he says, adding that others have failed in attempts to duplicate the product’s quality. Ron Gordon, National Sales Manager for Shurtape in Hickory, N.C., agrees. “Different manufacturers all think their colored tapes are better. 3M came out with the blue tape first. A number of other companies have tried to follow them. In every major test we’ve done, our tape is very comparable to theirs. But no, all color tapes do not perform equally, despite whatever claims are made.”

A

Patience and practicality can go a long way in preventing paint from creeping under the tape, says Gordon. “Creeping is usually due to either thin tape or poor application. People tend to hurry too much when masking off. They leave gaps and fail to rub tape down. Remember, this tape is called pressure-sensitive for a reason.”

Lord, who prefers to paint and de-mask as he goes, says paint creep is caused by tape that isn’t burnished down, or because of a contaminant on the surface. “If paint seeps under the tape, it can’t dry if we get the tape off quickly.” Lord advises burnishing tape “north and south” to get rid of pucker. “A lot of people only burnish one way, and they think they’re done. This causes peel-ups, which result in a lot more touch-up work.”

Tape will tear if it’s “dinged, dented or dropped,” says Lord. “You might have cheap tape, it may be cold, maybe it’s been outdoors, or the tape is old,” he says. Adds Young, “A lot of tape today is wrapped with vinyl film that shrinks with age. As it tightens on the roll, it bends down at the edge and causes cracks in the tape.”

Tape residue is another obstacle. “For the most part,” says Young, “you get residue from tapes with a rubber-based adhesive system. With acrylic adhesive, you’ll seldom get a transfer.” Removing residue doesn’t need to be a problem, notes Lord. “Anything with high solvent — oil-based paint thinner or anything with alcohol — will sit on the face of tape, and that moisture soaks through to release adhesives. Get a Q-Tip with rubbing alcohol, and that stuff wipes right off.”

Most paper masking tapes are not designed for rough surfaces such as brick or cinder-block surfaces. Duct tape is a popular option. “I use that sometimes if I have to tape over brick or cinder block,” says Franklin. “Then I take a masking machine with tape and put it over the duct tape. That works for very porous services and stone work, such as stone fireplaces.”

While the heavy-duty tapes have their uses, they are not suitable for applications such as drywall, wallcovering or enameled surfaces. “You need to know the adhesion quality of tape vs. the fragile state of your surface,” says Lord. “You must be very careful if masking onto a nicely stained piece of kitchen cabinetry. Varnish or stain can be taken off cabinetry.”

Climate also plays a role in determining a tape’s performance. “If a surface is too hot, the adhesive seems to melt,” says contractor Spencer Keim, owner of Spencer Keim Painting in Sunnyvale, Calif. “If a surface is too cold, the tape can’t adhere. Moisture, either humidity or rain, will keep tape from sticking.” Franklin adds that, although a surface might seem dry, condensation can build up with little notice. “When it’s cold sometimes, it’s difficult to get any tape to work real well,” says Franklin.

Contractors and manufacturers agree that tape should be removed slowly at an angle — between 45 and 90 degrees — away from the painted surface. “The biggest problem is that people tend to grab an end of the tape and just pull and run with it,” says Gordon. “If you pull at a 90-degree angle, you get a much better removal and the tape does not shatter. Don’t leave the tape on too long, and don’t be in a hurry. It takes just a few seconds longer to do it right.”

Adequate storage is the key to maintaining tape. “Either hang it on a roll, on an extended arm, or stack it flat or in a box,” says Lord. “You don’t want to have moisture in and out of it, then cold, then hot, then cold, then hot.” Sunlight, according to Keim, is tape’s greatest detriment. “Leaving tape in the back of a truck or in a hot van can age it fast. Excessive heat tends to dry the tape adhesive and can turn a premium tape into a low-quality one fast.”

The proper tape — properly preserved and properly applied — will go a long way in helping painters cut edges and corners successfully, contributing to a job well done.

|