Interior Paint, Metallic Paints

With metallic paints you get translucency, depth and shimmer. And with the shift away from fluorescent lighting to more use of incandescent and halogen, the metallic surfaces sparkle.

By Susan M. Brimo-Cox

It’s metallic paints. Metal mania, you might call it. In corporate offices, restaurants, clubs, resorts, casinos, retail spaces and private homes, metallic paints are the latest trend.

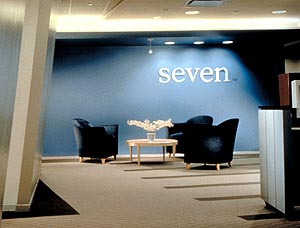

“It’s very cutting edge and new. Metallic paints are fun, zippy and millennium-looking,” reports Tara Hill, senior project designer with HOK Architects in Atlanta. For example, she says, “Many dot-coms use their interiors as recruiting tools, and metallic paints give the spaces a cool, youthful, energetic feeling.”

With metallic paints you get translucency, depth and shimmer. And with the shift away from fluorescent lighting to more use of incandescent and halogen, “the metallic surfaces sparkle,” says Hill. “Metallics play real well in natural light, too. You can see how that is with metallic automotive paints.”

“Lighting is absolutely critical to maximize the effects of metallic coatings,” explains Mark Hirons, senior associate with OWP&P Architects Inc. in Chicago. “Good lighting makes this product. The marriage of striking light design and this product delivers the ‘WOW’ impact.”

“As designers, we’re challenged to use innovative products [for all kinds of surfaces.] Metallic paints fit in well,” observes Hill.

What environments, locations and applications are ideal for metallic paints? If you talk to enough people, you’ll find there really isn’t any limit. But there are some things to consider — and the primary things really come down to cost. Metallic coatings aren’t cheap. You can “maximize the impact for the money spent for this product by using it in very visible, important areas, such as lobby areas and specialty spaces,” Hirons recommends. Touch up and repair can be difficult, too, he adds. That might be an important consideration if the application is a high-traffic area.

However, once you get past the cost issue, there is virtually a metallic paint product available to let you create whatever effect you want, wherever you want it.

The metallic look is a decorative element that goes back to Egyptian times, or perhaps even earlier. The origins of metallic coatings “are as old as people have been experimenting with pigments,” reports Scot Holland, managing director of the Gold Leaf and Metallic Powders Division of NEI Group in Los Angeles.

“Metallic powders are the raw pigment that can be added to any clear or pigmented medium, depending on the desired effect. The only rule is that the medium needs to be clear and be able to adhere. You can add metallic powders to urethanes, shellac, waxes, polyester resin, ceramic glazes, glass and more,” Holland says.

Metallic pigments come in two kinds of powders. (Neither of which should be confused with “powder coatings.”) Bronze powders are manufactured from metals: aluminum, brass, copper and zinc. Colored bronze powders are obtained by oxidizing, coloring and tinting the metal. Mica powders mimic metal, however mica reflects a rainbow of colors, so they are manufactured by bonding titanium dioxide and/or iron oxide on the surface of the mica flakes to control the light reflection, thus creating the desired colors. It is the reflection of light off the metal or mica particles that results in the “metallic” finish effect.

“The asset of powders made from metals is that the metallic coating is made from a pure metal, so it will react as the metal will, developing patina over time,” Holland says. “The asset of mica powders is that it isn’t a metal, so it won’t change over time.” On the other hand, metal reflects 100 percent of light, so it looks better than mica initially.

The typical vehicles you’ll see metallic powders combined with for painting applications are latex, lacquer, alkyd, epoxy and varnish mediums. You can purchase the powders and medium separately, but Monte Lazarus, president of Crescent Bronze Powder Co. in Chicago, says, “It’s important to know how to use the product. You have to have the right amount of powder for the amount of vehicle.” You will need less if you’re using finer pigments of 15 microns and below, more if you use coarser pigments of 30 microns or more, according to Lazarus.

Both Lazarus and Holland recommend “wetting” the pigment before mixing, using a solvent compatible to the vehicle medium. Mixing a pigment slurry into the medium makes the task easier.

Luckily, you can mix metallic powders in solvent-based mediums and store them. You can run into trouble with aluminum powders and water-based mediums, however, reports Lazarus. “Some metallics have aluminum powder — for example, gold tone has aluminum in it. When you mix aluminum in a water-based vehicle there is a chemical reaction [and a gas is created]. If you store that mixed, the containers can swell or explode.” Aluminum and latex, then, should be mixed on-site, in the quantity you need for the day.

If you don’t want to mix the powders and vehicle yourself, ready-mixed metallic paints are available in a rainbow of colors.

“Until recently, the only metallic paint products available for larger applications were extremely hazardous and noxious solvent-based systems created for the automotive finish industry. These products were designed for application in controlled environments and are entirely unsuitable for use as site-applied interior architectural finishes,” explains Roger Paulson, vice president/partner at Scuffmaster Architectural Finishes in Minneapolis. “Now, however, new technologies have emerged that have made water-based metallic products possible.”

Outside of the automotive industry, “original equipment manufacturers are really the only place to apply solvent-based metallic paints,” advises Jim Rogers, general manager of Modern Masters Inc. in North Hollywood, Calif., a manufacturer of pre-mixed, water-based metallic paints. Spray booths and protective gear are required for health and environmental concerns. And with new health and air-quality requirements, particularly in California, water-based products are filling a definite market need, he points out. “As metallic paints have become easier to use, they are being used in more environments and on more surfaces. You get the decorative effects, without all the hassle.”

For a smooth, automotive-style finish, the smoother the substrate the better, cautions Paulson. “Medium-density fiberboard (MDF) works great; properly-prepared sheetrock makes a good surface; metal, such as elevator doors and door frames, is also excellent.” In addition, “to achieve an exceptionally smooth finish with even distribution of metallic particles, it is necessary to spray-apply all components of the finish system-including any primer used.”

Conventional spray systems and high-volume, low-pressure (HVLP) spray systems will produce good results. Paulson explains, “Conventional systems offer the benefit of fast application and can be a good choice for large installations where the rate of production is critical. The downside to using conventional sprayer is the relative complexity of adjusting both air and fluid pressures to enable the product to be atomized while, at the same time, avoiding dryspray that will cause a texture on the finish.

“HVLP application offers the immediate benefit not requiring an air compressor. Less product misting occurs during HVLP application, resulting in a cleaner application process and more efficient use of material.” However, unless a higher-end HVLP unit is used, the metallic finish production rate may be slower than with conventional application. “HVLP application offers the immediate benefit not requiring an air compressor. Less product misting occurs during HVLP application, resulting in a cleaner application process and more efficient use of material.” However, unless a higher-end HVLP unit is used, the metallic finish production rate may be slower than with conventional application.

Airless spray systems are not recommended for applying metallic coatings.

John Houston, president of Giampolini & Co. in San Francisco says, “There’s definitely a learning curve with these materials. The whole success of your project depends on your surface.” On sheetrock, “you need a Level 5 finish on taping as a minimum,” he says. “The problem is not the paint, it’s the substrate preparation — it has to be better than normal.”

Jeff Maron, vice president of Stone Service Spray Painting in New York, agrees. Stone Service has applied metallic coatings at Kennedy Airport, at Sports Illustrated and to the Millennium Ball atop Times Square. “The surface has to be perfectly smooth,” he says. “Don’t look at it-feel it. If you can feel an imperfection, you’ll see it.” If you wind up with imperfections, Maron suggests using a semi-gloss instead of a high-gloss clear coat. “You can also splatter one metallic color over another to hide the imperfections and create a nice texture.”

“Metallic paints are also good as a base coat for faux finishes, such as crackling, glazing, ragging and sponging, and is [sometimes] better than traditional coatings,” says Rogers. “The metallics add depth; they’re more lively. In residential applications, they are used mostly on moldings and ceiling caps, but they are now sliding down the wall.”

“Anytime you put on a high-gloss finish, you need a smooth surface because flashing, textures and imperfections are amplified. The metallic powders reflecting light also amplifies imperfections,” observes Holland. What you can do in those circumstances when the substrate is not smooth is use the texture to your advantage, he says. Start with a metallic base coat and top it with layers of transparent washes for an antiqued look, he suggests. “The texture helps capture the glaze and gives the light something else to reflect off of.”

Concrete block, wood, particleboard and much more are candidates for metallic coatings-each offering a unique finish result. “We’re selling shimmering color, not just flat color,” Rogers explains. “Textured surfaces, like plaster knock-down, have a lot of light play.” New formulations of metallic paints with extender products offer the opportunity to add texture via roller application, with plenty of time for back rolling, he adds. This option with metallic paints may be of special interest for residential contractors and faux finish artists.

Metallic powders take on the properties of their carrier mediums. That means, how you apply them depends on what you’re using. The carrier medium also determines how durable the finish will be.

If you want to use metallic paints outdoors, make sure you use an exterior grade vehicle. Holland says metal powders work well outside if you want an ongoing patina look.

Indoors, smooth automotive-style finishes need a clear topcoat and they are not recommended for surfaces that are prone to damage-not necessarily because they can’t “take it,” but because repairs can be difficult. Just like a car’s finish, the amount of damage often sets the stage for the extent of the repair needed, as do the expectations of the client. Sometimes repairs are straightforward and a touch-up is all that’s needed. Other times an extensive repair may require reapplication from one visual break to another.

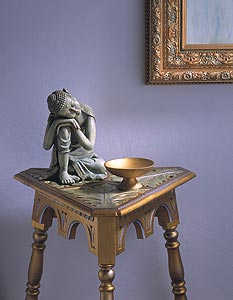

Judicious use of metallic paints can really deliver a rich, spectacular quality you can’t achieve with other coatings or materials. They integrate well with other paints, furniture and upholstery for a complete look.

“Metallic paint colors are generally available in the complete range of cool through warm hues, just like ordinary paints,” says Paulson. “Therefore, they can be easily color-coordinated with other interior colors — including fabrics and floor coverings. For instance, a space designed with a mostly neutral color palette can be phenomenally enhanced with either a neutral metallic color or — if the designer wants to make a statement — with a complimentary bright accent metallic color.”

Rich, saturated colors can also be used enhance metallics. The deeper paint color absorbs light and, by contrast, enhances the metallic’s light reflecting qualities.

Hirons says the current hot metallic colors are silvers, platinums and taupes — like champagne — and richer neutrals, such as copper and bronze.

Hill reports a cutting-edge trend is for matt metallics, a level below satin finish.

While metallic coatings may be relatively new to the painting contractor trade, they offer a lot of opportunity for up-selling. Cutting-edge in commercial applications; just getting on the burner for residential market — metallics are hot!

|